1. Introduction

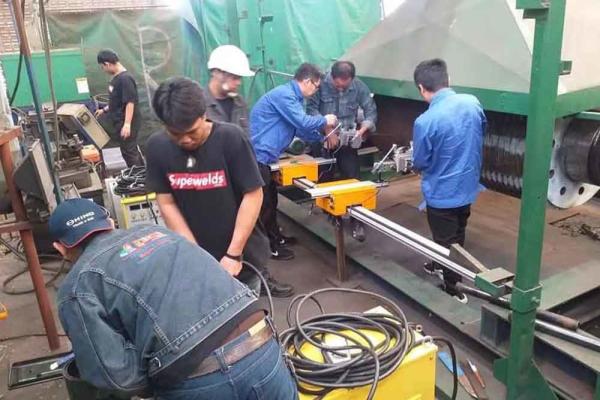

Jh-350-C surfing-welding machine is mainly composed of X and Y

automatic shafts, walking trolley, X and Y axis track, wire feeder,

welding gun, control system, welding power, circulating cooling

water tank, remote control device and other components.

1. X-axis and Y-axis automatic walking trolley: The shell of the

automatic walking trolley along the X and Y axes is made of

high-strength aluminum alloy die-casting technology, which is

durable, portable and light. Internally installed Japan SAMSR MOTOR

stepper motor control, SAMSR MOTOR series motor is SAMSR company's

motor, with rapid response, accurate positioning, is widely used on

robots.

2. X-axis and Y-axis travel track: It is die-casted from

high-strength aluminum alloy. The track consists of aluminum alloy

body and rack and guide rail. The rack and guide rail are embedded

in the aluminum alloy body. Each aluminum alloy track is 4m long,

and the user can configure X to 4 meters according to the actual

use. The length of the Y-axis guide is 1 meter.

3. Wire feeder: It adopts stepping motor and precision reducer to

drive four wire feed wheels at the same time. The wire feed wheel

has toothed flowers and good wear resistance. It is especially

suitable for 1.6mm-3.2mm flux cored wire. The wire is stable,

durable and so on. The wire inlet is equipped with a 5-wheel

straightener to ensure the welding quality of the straight wire.

4. Welding torch: Because long-term high-current welding will

inevitably lead to heat generation of the welding torch, affecting

the electrical conductivity and welding quality, the special

welding torch equipped with JH-350-C type surfacing machine adopts

double-circulating water cooling system to maintain the lower

temperature of the welding torch, so that the welding process

Continuously stable. With the unique welding gun angle adjustment

device, the angle of the welding gun can be adjusted arbitrarily,

and the all-round welding of the pressing roller can be easily

realized.

5. Control system: TECO's AP series PLC and stepper motor are used

to achieve precise positioning and intelligent control. The

equipment has been highly praised by the market for its stability,

reliability, rich functions and high degree of automation. With the

special automatic welding procedure, it has the advantages of

simple operation and high intelligence.

6. Wireless remote control device: All control functions are

concentrated on the remote control device, integrating X/Y axis

movement, wire feeder operation, engineering teaching, welding

control and other functions, which is very convenient to use. And

an emergency stop button is provided to provide security.

2. Technical Parameter

| Maximum clamping length | 1200mm |

| Maximum loading diameter | 400mm |

| Maximum load | 1500kg |

| Welding swing width | 5-80mm |

| Welding swing speed | 0.1-3.5M/min |

| Rotation speed | 0.05-0.3r/min |

| Welding voltage | 0-45V |

| Welding Current | 300-750A

|

ADVANTAGES OF HARDFACING TECHNOLOGIES

Prolongs the life of parts and increases efficiency

Reduces equipment downtime as it keeps equipment longer working.

Productivity and profitability is increased

Reduction of spare parts inventory.

Resurfaced parts will help to reduce stocks of new parts normally

required for emergency and general replacement

Reduced power (energy) consumption.